Yokohama develops first model for predicting rubber wear on surfaces

Yokohama Rubber Co., Ltd., announced today that through joint research with Dr. Bo Nils Johan Persson, a leading expert in the study of rubber friction and contact, it successfully developed in December, 2024, the world’s first theoretical model to predict the rubber wear-rates on uneven road surfaces and the size distribution of wear particles. This research was selected as the most noteworthy item and featured as the cover story in the February 21, 2025 edition of “The Journal of Chemical Physics” (published by the American Institute of Physics).

Dr. Persson is a globally renowned researcher in the fields of contact, friction, wear, and lubrication, including rubber friction. He works at Peter Grünberg Institute (Germany) and Lanzhou Institute of Chemical Physics (China) and runs a company called Multiscale Consulting (Germany) that supports companies in the rubber industry and beyond in addressing various challenges. Dr. Persson’s unique approach to contact mechanics and rubber friction has been documented in numerous peer-reviewed academic journals and verified by other scientists, proving its effectiveness in solving a wide range of problems.

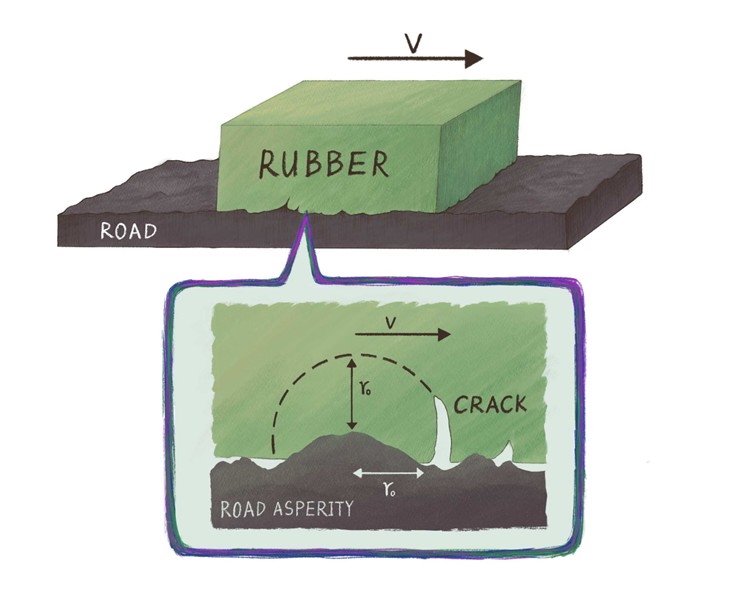

Yokohama, recognised for its extensive track record in rubber research and advanced technological development capabilities, entered into a contract with Multiscale Consulting to collaborate with Dr. Persson in studying friction and wear on rubber and road surfaces. As a result, they successfully developed the world’s first theoretical model for multiscale (ranging from nanometer to centimeter levels) rubber wear behaviour on uneven road surfaces, for which theorisation had been difficult in the past.

Experiments measuring rubber wear behaviour when sliding in both dry and wet conditions at different contact pressures and sliding speeds showed that the theoretical model’s predictions of wear-rates (mass loss per unit of sliding distance) and size distribution of wear particles aligned closely with the experimental results, confirming that the model could be used for such predictions.

Going forward, Yokohama plans to continue conducting research with Dr. Persson and Multiscale Consulting in order to pursue the development of tyres with high-level wear resistance. Additionally, the company aims to contribute to resolving environmental issues caused by tyre wear, which is becoming increasingly important amid the increase in heavy electrified vehicles such as EVs.

Under Yokohama’s three-year (2024–2026) medium-term management plan, Yokohama Transformation 2026 (YX2026), Yokohama is implementing technology and production strategies based on a motto of “low cost, speedy development of quality products” that will strengthen the entire Yokohama Group. As part of this initiative, the company is pursuing innovation in rubber material and tyre design technologies, leveraging AI, and promoting joint research with universities, companies, and professional organisations.